South African Mines Make Strides in Safety with 100% Employee Alcohol Testing

By: Nicola Grun

Precision Safety Appliances (PSA) based in Durban, South Africa has been an exclusive Lifeloc distributor in South Africa since 2005. PSA offers Lifeloc breath alcohol testing instruments to a number of industries including Mining, Law Enforcement, Oil and Gas, Manufacturing, Transportation, Port Operations, Rail, Construction and Healthcare Facilities. I recently spoke with Michael Crossland, Product Manager of the Substance Abuse Division for PSA, to learn more about the recent Mining Industry successes of Lifeloc’s new SENTINEL™ Alcohol Screening System since its introduction. Michael was happy to share his success with me.

Background

PSA markets and sells Lifeloc products and fulfills its customers’ service needs throughout the product life cycle. As an authorized Lifeloc service center, PSA performs maintenance and calibration on Lifeloc testing devices. Michael visited the company’s Colorado headquarters in 2011 to become a certified Lifeloc Master Trainer. This certifies him to train Calibration and Service Technicians, Equipment Operators and Provisional Instructors. PSA shares the same service philosophy as Lifeloc: both strive to provide the best after-sales customer service possible. PSA also assists its customers with professional advice and recommendations for establishing substance abuse policies in the workplace.

South African mines are governed by Act 29 of that country’s 1996 Mine Health and Safety Act stipulating that it is the owner’s responsibility to identify and address potentially hazardous work conditions. In 2003 the country’s mining sector made a commitment to reduce mining deaths by 20% per year and set its sights on achieving safety levels comparable to mines in Australia, Canada and the United States. The Mine Health and Safety Inspectorate of South Africa enforces these standards to reduce deaths and occupational injuries. The efforts are paying off as is evidenced by the 2010 fatality rate of 128, a decrease from 270 deaths in 2003. According to Michael, "Demand for The SENTINEL™ continues to increase from the mines and other safety-sensitive industries looking to take their safety performance to the next level."

Guarding Mine Safety with The SENTINEL™

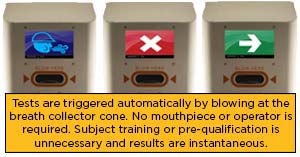

Lifeloc’s SENTINEL™ Alcohol Screening System is now used extensively in South African mines. It provides automated "zero tolerance" breath testing which has become an essential element of South African mine safety. It offers automated testing that suits the diversity and large employee population of the mining industry well. Test recovery time between subjects is immediate on negative results and less than 20 seconds on positives. To simplify operations further, the device is connected to a card swipe machine that monitors employee timecards. According to Michael, "The SENTINEL provides a cost effective, reliable and totally automated solution for routine daily testing of large employee populations." Because of the high volume of people entering the mines through turnstiles throughout the day, a SENTINEL™ automated alcohol screening station installed at each turnstile enables easy screening of everyone entering the mine. No employee or supervisor training is required. There are no mouthpieces to worry about and best of all the security staff is free to work elsewhere on site.

The SENTINEL’s color LCD screen guides employees effortlessly through testing. Internationally recognized color icons prompt users to blow into the collection cone and the two-second test is triggered automatically. Negative (no alcohol) results register immediately and positive results are detected in less than 10 seconds. Test results are instantly relayed to the access control system to allow or deny entry. Michael commented that, "Testing is so fast and easy the mines are now able to conduct 100% employee testing in less time and at lower cost than it previously took to do random employee screening with handheld breathalyzers." PSA’s first mining customer now screens 100% of employees entering the site versus a previous random testing rate of just 30%. Approximately 2,000 employees are routinely screened through five turnstiles daily without bottlenecks. The SENTINEL™ can perform approximately 360 tests per hour versus traditional handheld testers which operate at a rate of about 60 persons per hour.

Service and device calibration are easy since both can be performed in-place without returning the unit to the factory. "The inclusion of Lifeloc’s proven breathalyzer technology is what sets The SENTINEL™ apart from any other entrance-style products out there," said Michael. "The speed at which the device is able to respond and recover to negative and positive results makes it the best solution for any customer wishing to integrate their access control and breath alcohol testing."

PSA worked hand-in-hand with Lifeloc in development of the new generation passive screener. Multiple client requests for a fixed breathalyzer system linked to an access control system prompted PSA to research the market for solutions. Few products existed and none met the need for ease of use, speed and reliability. Although the South African market is flooded with cheap, mass produced handheld breathalyzers that can be purchased online, Michael states the majority of customers choose Lifeloc because of their reliability. He concluded my interview by stating, "Safety sensitive environments cannot afford to mess around with questionable results." Lifeloc plans to continue working with PSA to co-develop products for targeted market needs. Next on the horizon is an enhanced SENTINEL™ with biometric capabilities.